Modern Sap Collection Techniques

Jul 14, 2024

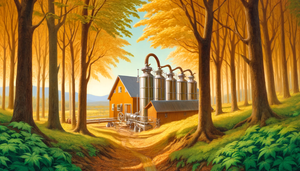

Maple syrup production in Vermont is a tradition that locals and visitors cherish. The comforting aroma of boiling sap, the rich taste of freshly made syrup, and the picturesque landscape of sugar maple trees have made this state a prime destination for maple syrup lovers. However, the methods of sap collection have evolved significantly over the years. This transformation, driven by technological advancements, has enhanced the efficiency and sustainability of syrup production while preserving its artisanal quality.

The Evolution of Sap Collection

Traditional Methods

For generations, sap collection in Vermont was a labor-intensive process. Farmers would drill holes into sugar maple trees, insert spouts, and hang buckets to collect the dripping sap. These buckets were manually emptied into larger containers and transported to the sugarhouse for boiling. While effective, this method was time-consuming and required significant manual labor.

Introduction of Tubing Systems

In the mid-20th century, a significant innovation emerged, which was the introduction of plastic tubing systems. These systems connected multiple trees, allowing the sap to flow directly from the spouts into a central collection point via gravity. This reduced the need for manual collection and increased efficiency. The tubing system also helped minimize contamination, as the sap was less exposed to the elements.

Modern Vacuum Systems

How Vacuum Systems Work

The most notable advancement in sap collection technology is the use of vacuum systems. These systems create a gentle vacuum that helps draw sap from the trees more efficiently than gravity alone. The vacuum system consists of a network of tubing connected to a vacuum pump, which maintains a constant suction force, encouraging a steady flow of sap.

Benefits of Vacuum Systems

- Increased Yield: Vacuum systems significantly increase sap yield, allowing producers to collect more sap per tree. This is particularly beneficial during periods of less favorable weather conditions when sap flow might otherwise be limited.

- Consistency: The constant vacuum helps maintain a steady sap flow, ensuring a more consistent collection rate and improving overall production efficiency.

- Healthier Trees: Contrary to concerns, vacuum systems do not harm the trees. They can promote better sap extraction without causing stress or damaging the trees.

- Reduced Labor: These systems drastically reduce the manual labor required for sap collection, allowing producers to focus more on the boiling and processing stages.

Sustainability and Environmental Impact

Sustainable Practices

Modern sap collection techniques, particularly vacuum systems, support sustainable syrup production. Producers can operate more efficiently and with less environmental impact by maximizing sap yield and minimizing waste. Additionally, many Vermont producers are committed to organic practices, ensuring that the forests remain healthy and productive for generations to come.

Energy Efficiency

Technological advancements also extend to the sugarhouses where sap is boiled into syrup. Energy-efficient evaporators and reverse osmosis machines reduce the amount of fuel needed to boil sap, further contributing to the sustainability of the process.

Embracing Tradition with Technology

While technology has transformed how sap is collected, the essence of Vermont maple syrup production remains deeply rooted in tradition. Producers continue to honor the artisanal methods passed down through generations, ensuring that each bottle of syrup reflects Vermont's rich history and natural beauty.

Tasting the Difference

For maple syrup lovers, using modern techniques enhances the quality and flavor of the syrup. The efficient collection and processing methods ensure that the syrup retains its pure, natural sweetness and distinctive maple flavor, beloved by foodies, chefs, and breakfast enthusiasts.

Supporting Local Producers

By choosing Vermont maple syrup, consumers support local farmers who are committed to sustainable and environmentally friendly practices. This not only preserves the tradition of maple syrup production but also contributes to the local economy and the conservation of Vermont’s beautiful forests.

Frequently Asked Questions (FAQs)

Q: Do vacuum systems harm the trees?

A: No, vacuum systems are designed to be gentle and do not harm the trees. They promote efficient sap extraction without causing stress or damage.

Q: Is modern maple syrup still considered artisanal?

A: Yes, despite the use of modern technology, Vermont maple syrup is still produced with a strong emphasis on quality and tradition, maintaining its artisanal nature.

Q: How has technology impacted the flavor of maple syrup?

A: Technology has helped improve the consistency and quality of syrup, ensuring a pure and natural flavor that is true to Vermont’s maple syrup heritage.

Q: Are there environmental benefits to modern sap collection techniques?

A: Modern techniques such as vacuum systems and energy-efficient evaporators reduce waste and energy consumption, making the process more sustainable.

Modern sap collection techniques, including vacuum systems, have revolutionized Vermont’s maple syrup production. These advancements have increased efficiency and sustainability while preserving the rich traditions and high quality that define Vermont maple syrup. By embracing these innovations, Vermont producers continue to offer a product that delights the senses and supports a sustainable future.